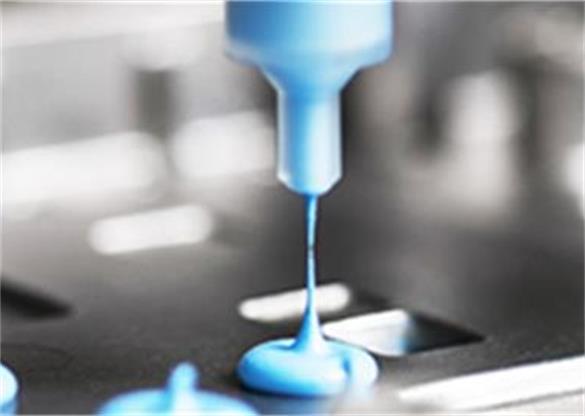

PUR hot melt adhesive injection technology melts the PUR and then injects to mold set cavity or dispenses it with low air pressure. PUR hotmelt adhesiveis a kind of reactive hot melt adhesive solidified after reaction with water molecules. Under the condition of inhibiting the chemical reaction, The PUR is melted by heating, and the PUR between the two products are condensed and cooled to serve as positioning function (physical reaction). Then, by the moisture in air and the moisture on the surface of the adhesive, it can expand the chain to form a polymer (chemical reaction) with high cohesion. The adhesive strength, heat resistance and low temperature resistance will be further improved. After complete solidification, it has excellent bonding strength, solvent resistance, paint resistance, heat resistance, hydrolysis resistance, etc. Due to its high reactivity.

With special PUR dispensing equipment, you can dispense only 1mm width glue line. Even the thin layer can guarantee high bonding strength. This thin layer also ensures that customers have the strength they need to achieve a lighter, thinner and more beautiful portable handheld design.

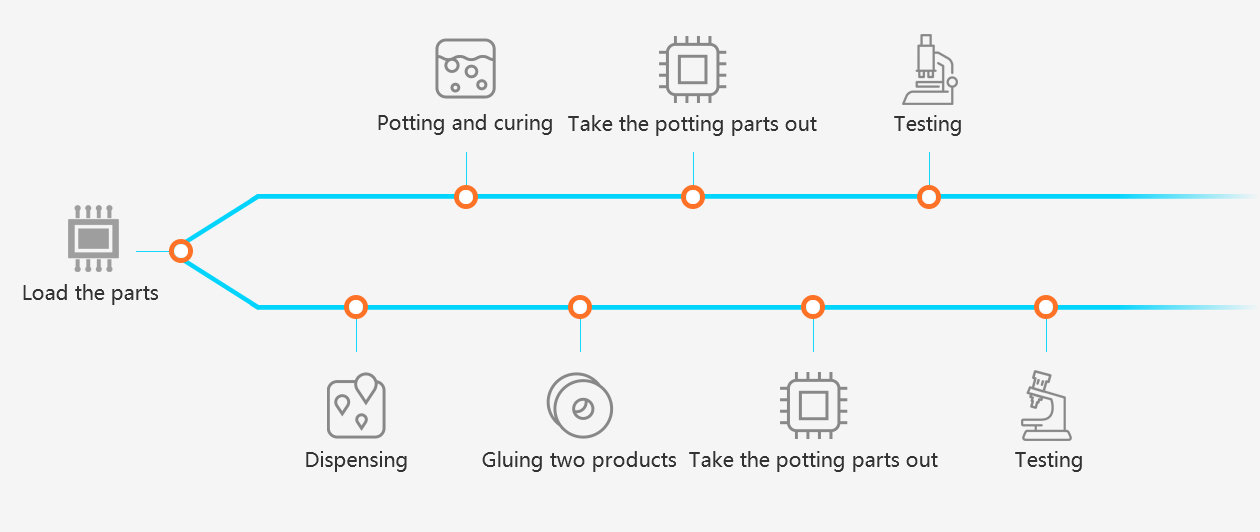

The complete process of PUR hotmelt glue injection molding/dispensing is composed of the hotmelt glue injection molding machine/dispenser, the mold set and the process parameters.

| 1. Low viscosity | 2. 100% solid content |

| 3. Good water resistance | 4. Excellent bonding strength |

| 5. Good solvent and paint resistance | 6. High initial adhesion,fast positioning |

| 7. Anti-aging, anti-drop, good impact resistance | 8. Excellent resistance to high and low temperature |

| 9. No dispensing stringy.Low Working temperature | 10.RoHS,Reach,halogen-free,No water or solvent Evaporate |

bonding the frame and touch screen of various electronic products (such as mobile phone and tablet computer).It is alswidely used in the adhesion of glass,metal ceramic,rubber and plastics substrates in the microelectronics industry.

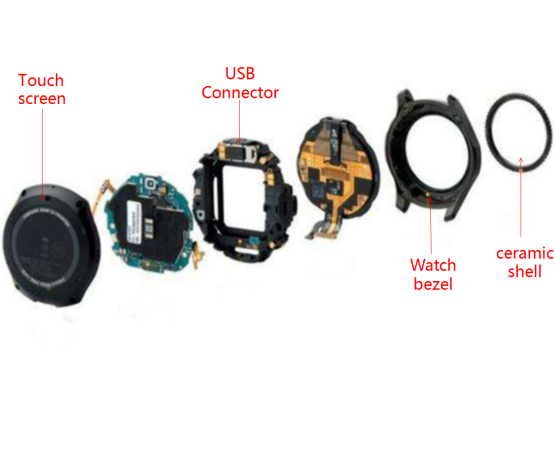

PUR hotmelt adhesive applied in smart watch and smart wear project:

1. Bonding the frame and touch screen

2. Watch bezel and ceramic shell

3. USB connector sealing

PUR hotmelt adhesive is a moisture curing reaction polyurethanes hotmelt adhesive. It is a kind of reactive hot melt adhesive solidified after reaction with water molecules. Under the condition of inhibiting the chemical reaction, the PUR is melted by heating, and the PUR between the two products are condensed and cooled to serve as positioning function (physical reaction). Then, by means of the moisture in air and the moisture on the surface of the adhesive, it can expand the chain to form a polymer (chemical reaction) with high cohesion. The adhesive strength, heat resistance and low temperature resistance will be further improved. After complete solidification, it has excellent bonding strength, solvent resistance, paint resistance, heat resistance, hydrolysis resistance, etc.

PUR hotmelt adhesive specification | |

Appearance | Appearance Milky white. After melting, the liquid is translucent. |

Opening time( at 120℃) | 120-240 Second |

Density(g /cm3) | 1.15 |

Viscosity(cps, 120℃) | 6500-8000 |

Application Temperature(℃) | 110-120 |

Operating Temperature(℃) | -40~130 |

Solvent | No solvent |

LPMS sells all kinds of models of PA/PO/PUR/Polyester hot melt adhesives,

provide professional technical guidance and service to meet the different needs。

LPMS have standard production service department and manufacturing shop to provide small/larger quantities productions service and testing service. Service includes SMT, DIP plug-in, lead-free process, welding process, low pressure molding, testing, package and new part design service.

Copyright ? 2015-2018 LPMS International Ltd. All Rights Reserved.